The most significant feature of our technology is the use of alumina balls as a heat carrier.

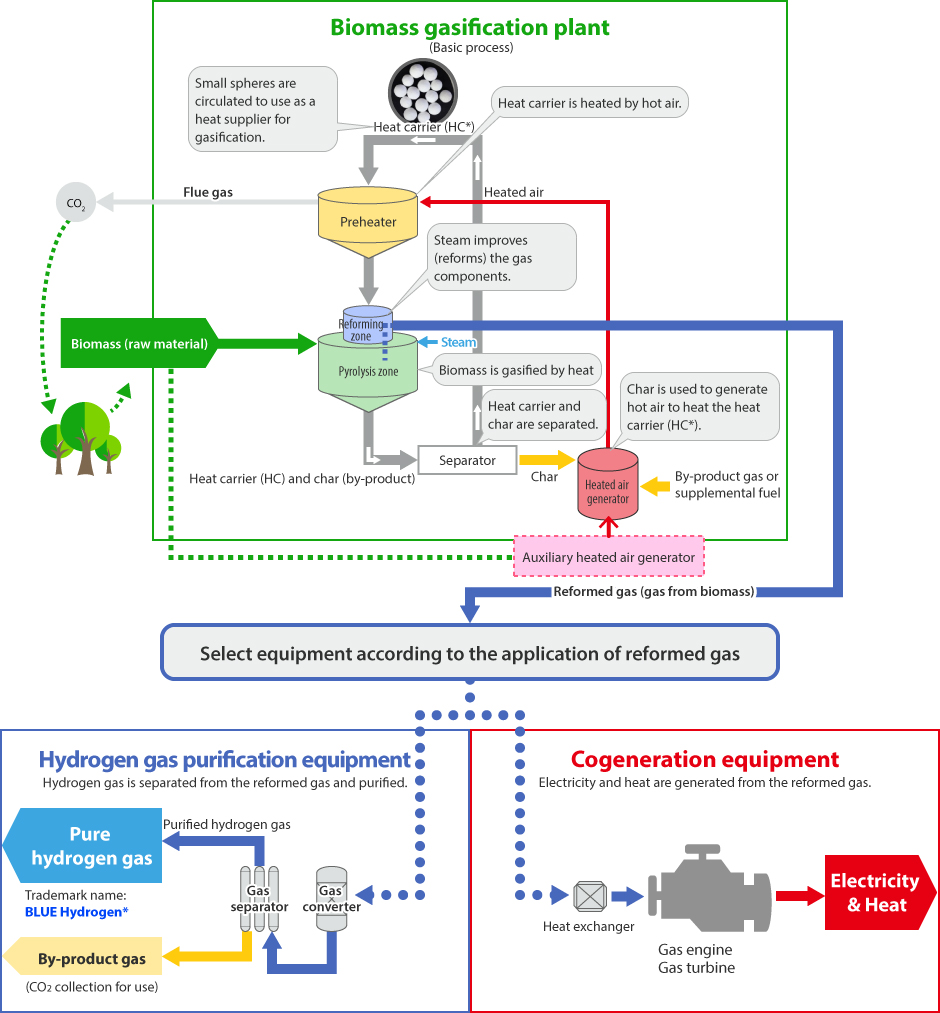

In the pyrolysis zone, biomass materials such as woodchips and sewage sludge contact many alumina balls heated to high temperatures to generate the pyrolyzed biogas contains hydrogen, CO, CO2, and methane. Moreover, in the reforming zone, the biogas contacts the higher temperature alumina balls and steam where biohydrogen is produced via the steam reforming reaction.

These circulating alumina balls not only transfer heat to each part but also inhibit and remove tar generation that is the major factor in equipment problems, such as blockages in conventional plants.